- No.280/A, Gramani Street, Railway Station Road, Korattur, Chennai - 600 080.

- +044 - 3557 1493

Excellence in & Every Delivery

At Prime Tech Engineering, we are dedicated to the art of precision engineering, delivering expertly crafted components that cater to a wide range of industrial applications.Our products are designed to meet the most stringent industry standards, ensuring exceptional quality, durability, and reliability.

About us

Excellence in Precision Engineering | ISO 9001:2015 Certified for Over 18 Years

At Prime Tech Engineering, we take immense pride in being a trusted partner for delivering high-quality precision components that are meticulously tailored to meet the unique and evolving requirements of our clients. With over 18 years of experience, we have built a solid reputation for excellence in precision engineering, becoming a cornerstone for industries that demand the highest standards of quality and reliability.

What We Offer

Our Expertise in Precision Engineering

- Precision Components: At Prime Tech Engineering, we specialize in manufacturing high-quality precision components that cater to the exacting needs of control valves, pumps, and a wide range of other engineering applications.

- Custom Manufacturing: We excel in delivering tailor-made manufacturing solutions designed to meet the unique requirements of our clients. From conceptualization to final production.

- Reliable Outsourcing Services: Our outsourcing services provide a seamless extension to your manufacturing processes. We offer a comprehensive range of services, including vertical milling, welding overlays, grinding, and heat treatment, utilizing advanced machinery and techniques.

Delivering high-quality components with unmatched accuracy and innovation, Prime Tech Engineering ensures exceptional solutions for control valves, pumps, and engineering industries.

Precision Engineering Excellence

we specialize in creating advanced component designs that push the boundaries of functionality and efficiency.

Innovative Component Design

We build strong, long-term relationships with industry leaders to enhance our capabilities and deliver superior solutions.

Strategic Industry Partnerships

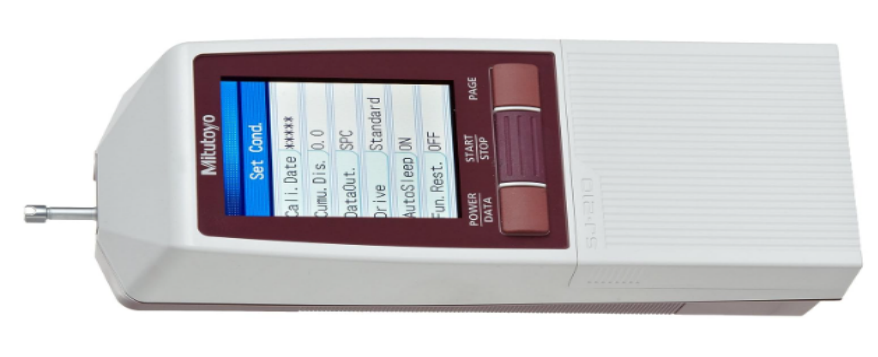

Measurement Instruments and Tools

Ensuring Uncompromising Accuracy and Quality at Every Stage

Mitutoyo Make – Renowned for their high precision, our Mitutoyo instruments guarantee exceptional accuracy and reliability.

PMI (Positive Material Identification) – Essential for verifying the material composition and ensuring the correct materials are used for every component.

Digital Measuring Tools – Equipped with advanced digital surface finish testers, Vernier calipers , we ensure precise measurements and surface quality.

Standard Measuring Tools – Includes micrometers (up to 300mm), bore dial gauges, and lever dial gauges to measure critical component dimensions with high precision.

Advanced Measurement Equipment – Our 2D Height Gauge (450mm) provides detailed height measurements, offering enhanced precision for complex geometries.

Supporting Tools – Magnetic “V” blocks, surface roughness comparators, surface tables (630 x 630), bevel protractors, and thread pitch gauges help maintain consistent measurements for a variety of applications.

100

Precision Manufacturing

100

Custom Engineering Solutions

100

Quality Assurance

100

Timely Delivery

Expertise in Diverse Materials for Precision Solutions

Material Expertise in SS, MS, and Alloys

At Prime Tech Engineering, we specialize in working with a wide variety of materials to cater to the diverse needs of our clients across industries. Our expertise extends to all types of Stainless Steel (SS) and Mild Steel (MS) grades, as well as high-performance specialty alloys, ensuring that we can meet even the most demanding application requirements.

We handle a broad range of materials, including but not limited to:

- Stainless Steel Grades: SS 303, 304, 316, and 316L

- Specialty Alloys: Stellite, Monel, Inconel, Hastelloy, and UNS 31254

- Nitronic Series: Nitronic 50

- Forged Steel Grades: F11, F22, and A105

- Precipitation-Hardening Steel: 17-4 PH and SS410

- Non-Ferrous Metals: Aluminium and Brass

Our ability to work with such a diverse range of materials allows us to deliver solutions tailored to specific performance criteria, such as corrosion resistance, strength, durability, and machinability. Each material is sourced from trusted suppliers and rigorously inspected to meet the highest quality standards.

Our Strengths The Core of Our Precision and

The Core of Our Precision and

Number of Reliability

Advanced Machining Facilities

Equipped with state-of-the-art CNC turning centers, DRO machines, and heavy-duty lathes, we guarantee high-precision manufacturing.

Comprehensive Inspection Tools

Leveraging Mitutoyo measuring instruments, PMI systems, and digital testing tools to uphold stringent quality control standards across all products.

Experienced Workforce

Our skilled team of highly dedicated professionals is committed to delivering defect-free products, ensuring every detail is meticulously executed to meet the highest standards.

Business Consulting

It is almost impossible to make strategic decisions without deep knowledge

Project Management

It is almost impossible to make strategic decisions without deep knowledge

Versatile Material Handling

We have extensive expertise in working with a wide range of materials, including stainless steel, brass, aluminum, and specialty alloys, to meet diverse client needs.

Custom Manufacturing Capabilities

We offer tailored solutions to meet unique client specifications, ensuring each product is designed and crafted to perfection.

Timely On-Time Delivery

With our efficient production processes and reliable supply chain management, we consistently deliver products on schedule, ensuring customer satisfaction and trust.